Edge (End) Hardened Steel Cheese Tubes

| Sr. No | Dimensions | Weight | Tensile Strength | ||

|---|---|---|---|---|---|

| ID | Thickness | Length | (+/- 5 gms) | MPa | |

| 1 | 32 | 1 | 218 | 182 | 700 |

| 2 | 32 | 1 | 230 | 190 | 700 |

| 3 | 35 | 1 | 218 | 195 | 700 |

| 4 | 35 | 1 | 230 | 202 | 700 |

| 5 | 35 | 1 | 218 | 195 | 700 |

| 6 | 35 | 1 | 230 | 202 | 700 |

| 7 | 35 | 1.5 | 218 | 295 | 580 |

| 8 | 35 | 1.5 | 230 | 315 | 580 |

| 9 | 37 | 1 | 218 | 200 | 700 |

| 10 | 37 | 1 | 230 | 220 | 700 |

We have specially developed Edge (End)

Hardened Cheese tube for overcoming the problem of deformation and damage during handling and

transportation.

Product Features

High Tensile Cold Drawn Steel Tubes

The center portion of cheese tube have good

mechanical strength to withstand winding pressure

Light Weight Cheese Tube

Precisely Controlled Dimensions

Length as per customer requirement

Perfect Roundness and Straightness

Better Hardness

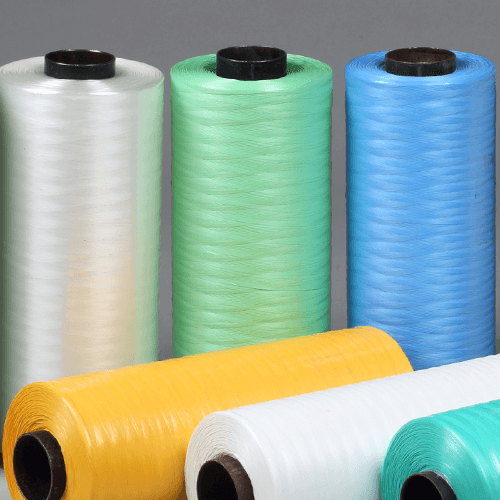

Powder Coating in Different available

Colour like Black, Red, Yellow, Blue, Green, White or any other color as per the customer requirement.

Precise Chamfering with the 90 Degree Right

angle cutting.

Advantages

Long life due to better Mechanical

Properties

Lowest rates

Save Electricity and Maintenance cost

because of the light weight of the Tubes

Better fitment due to Precise Dimensions

Better weaving quality due to perfect tube

Roundness

Better performance Due to accurately

straightened tubes